Copper, zinc and lead concentrate filtration plant

Project overview

- Customer: Aurelia Metals Limited (AMI)

- Country: Australia

- Application: Copper / Zinc / Lead

- Production: 17.5 T/h (Copper), 15.2 T/h (Zinc) y 17.0 T/h (Lead)

Discover our wide range of filter presses for the mining industry.

Leading Filtration Technology for multiple mining applications

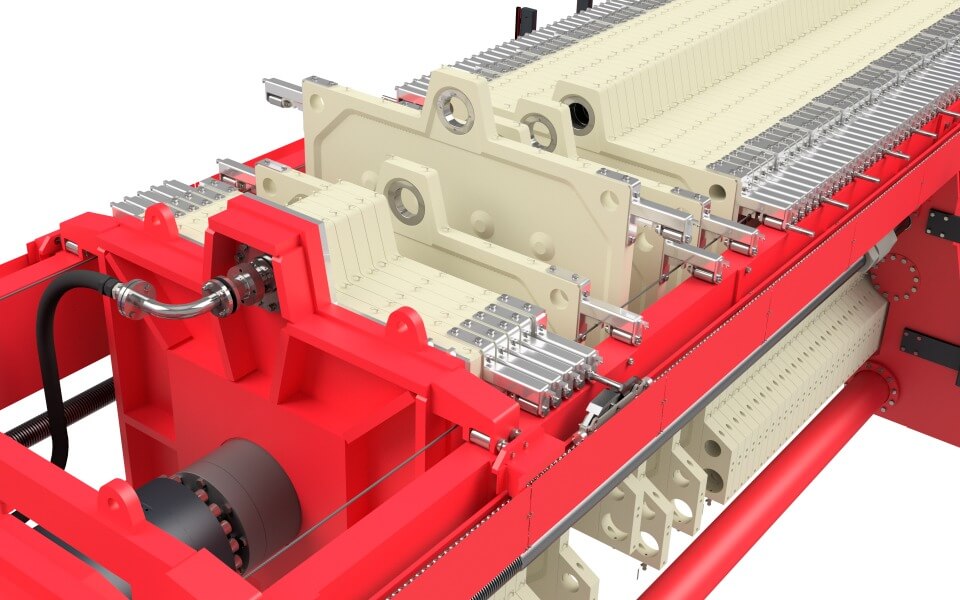

Medium capacity filtration process and quick discharge

Developed for medium capacity filtration processes of metallic minerals, industrial minerals, coal and tailings. APN filter presses come with numerous configurations. They can be fitted with plates of different sizes, materials, configurations (chamber or membrane) and with a wide range of filter plate pack opening solutions.

High capacity filtration process

The APNH range of high-capacity filter presses has been specifically designed for high-pressure filtration processes, which turns them into ideal devices for the filtration of mine tailings. APNH filter presses come with numerous configurations. They can be fitted with plates of different sizes, materials, configurations (chamber or membrane) and with a wide range of filter plate pack opening solutions.

Success stories

Cutting edge technology for the mining industry

More than 50 years of experience.

We have collaborated with some of the world's most important mining companies.

Reduces OPEX compared to other solutions on the market.

Present in more than 40 countries.